Design and Working Principle of Belt Tensioner Pulley

-

1. Functionality

The belt tensioner pulley is designed to maintain proper tension on the engine belt, ensuring smooth operation of various engine components.

-

2. Structure

It consists of a spring-loaded arm and a smooth pulley wheel that rotates as the belt moves, allowing for consistent tension.

-

3. Material

The pulley is typically made of durable materials like steel or aluminum to withstand the rigors of engine operation.

-

4. Working Principle

As the engine belt rotates, the tensioner pulley adjusts its position to maintain the optimal tension, preventing slippage and wear.

-

5. Importance

Proper functioning of the belt tensioner pulley is crucial for the overall performance and longevity of the engine system.

What happens when a belt tensioner fails?

-

1. Belt Slippage

Due to lack of tension, the belt may slip off the pulleys, causing engine components to malfunction.

-

2. Increased Wear

Excessive wear on the belt and other components can occur, leading to potential breakdowns.

-

3. Noisy Operation

A failing tensioner pulley may produce squeaking or grinding noises as it struggles to maintain tension.

-

4. Engine Overheating

Improper belt tension can cause the engine to overheat due to inefficient operation of cooling systems.

-

5. Reduced Performance

A failed tensioner pulley can result in decreased power output and overall performance of the engine.

How do I know if my belt tensioner pulley is bad?

-

1. Squeaking or Grinding Noises

Unusual sounds coming from the engine area may indicate a worn-out pulley.

-

2. Belt Misalignment

If the belt appears misaligned or is slipping off the pulleys, the tensioner may be failing.

-

3. Excessive Belt Wear

Inspect the belt for signs of wear, cracking, or fraying, which could be caused by a faulty tensioner.

-

4. Engine Overheating

If your engine is running hotter than usual, it may be due to a malfunctioning tensioner pulley.

-

5. Loss of Power Steering

A failing tensioner pulley can also impact power steering operation, making it harder to turn the wheel.

Advantages of Belt Tensioner Pulley

-

1. Enhanced Engine Performance

Proper tension maintenance leads to optimal engine performance.

-

2. Increased Component Lifespan

By reducing wear and tear, the pulley helps extend the lifespan of engine components.

-

3. Improved Fuel Efficiency

Efficient belt operation can contribute to better fuel economy.

-

4. Reduced Maintenance Costs

Preventative tensioner pulley maintenance can save on costly repairs in the long run.

-

5. Smooth Engine Operation

A properly functioning pulley ensures smooth and quiet engine operation.

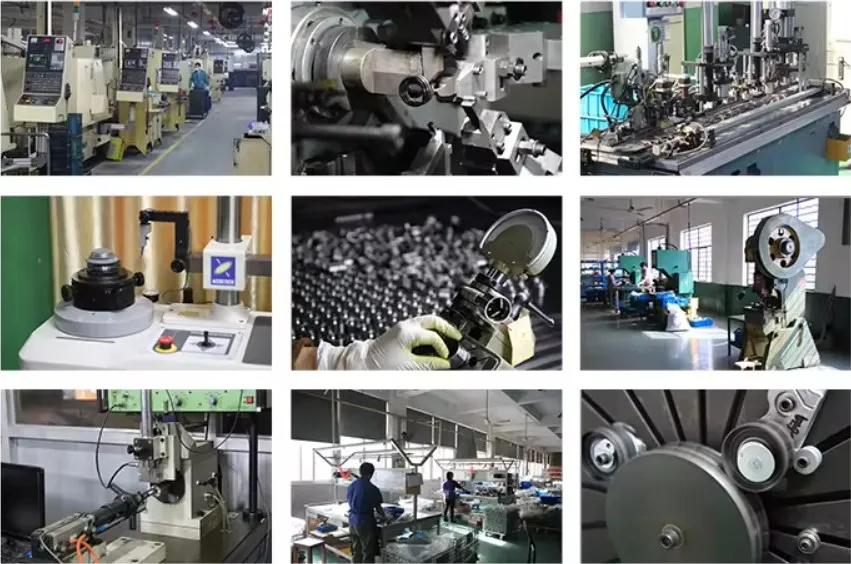

Process of Belt Tensioner Pulley

-

Mold

The initial mold design is created to form the shape of the tensioner pulley.

-

Casting

The molten metal is poured into the mold to create the pulley's structure.

-

Raw Materials

Durable materials like steel or aluminum are used to ensure longevity.

-

Production

The pulley is manufactured using precision machinery and techniques.

-

Testing

Each pulley undergoes rigorous testing to ensure quality and performance.

-

Antirust Treatment

A protective coating is applied to prevent rust and corrosion.

-

Seperate Inspection

Individual inspection is conducted to verify the pulley's integrity.

-

Marking

Each pulley is marked with identification information for traceability.

Should I replace belt tensioner or just pulley?

-

1. Inspection

It is recommended to inspect both the tensioner and pulley for wear before deciding.

-

2. Age of Components

If both are of similar age, replacing both may be a wise choice to prevent future issues.

-

3. Cost Consideration

Compare the cost of replacing the tensioner alone versus both components for cost-effectiveness.

-

4. Overall Condition

If the tensioner shows signs of wear or damage, it may be best to replace both for optimal performance.

-

5. Professional Advice

Consulting with a mechanic or expert can provide guidance on the best course of action.

How does a belt tensioner pulley work?

-

1. Tension Adjustment

The pulley automatically adjusts its position to maintain proper tension on the engine belt.

-

2. Smooth Rotation

As the belt moves, the pulley wheel rotates smoothly to prevent slippage and ensure consistent operation.

-

3. Spring Mechanism

A spring-loaded arm provides the necessary tension to keep the belt in place under varying conditions.

-

4. Engine Synchronization

By synchronizing with the engine's movements, the pulley helps maintain proper timing and operation.

-

5. Component Protection

The pulley protects engine components by reducing stress and wear on the belt and associated parts.

About HZPT

HZPT, founded in 2006, is a leading manufacturer of precision transmission components based in Hangzhou. We specialize in producing various machined parts and can customize products to meet your specific requirements. Our company has a strong reputation in Europe and North America for providing top-quality products and competitive prices.

Before establishing our overseas sales team, we began producing 3D printer parts, security screws and nuts, camera mounts, and more. We also offer assembly production services to streamline the manufacturing process and save time and costs. Whether your project is large or small, we are committed to providing the best quality components and services to meet your needs. Partner with us early on, and we will help you spend wisely!