Design and Working Principle of Belt Tensioner Pulley

-

Point 1: Functionality

The belt tensioner pulley is designed to maintain proper tension on the drive belt in a vehicle's engine, ensuring smooth operation and preventing slippage.

-

Point 2: Construction

Constructed with high-quality materials, the belt tensioner pulley features a durable design to withstand the rigors of engine operation.

-

Point 3: Bearings

Equipped with precision bearings, the belt tensioner pulley ensures smooth rotation and minimal friction for optimal performance.

-

Point 4: Adjustability

The belt tensioner pulley is adjustable to maintain the correct tension on the belt as it stretches over time, ensuring reliable operation.

-

Point 5: Working Principle

By applying tension to the drive belt, the belt tensioner pulley helps transfer power from the engine to various components, such as the alternator and air conditioning compressor.

What happens when a belt tensioner fails?

-

Point 1: Drive Belt Slippage

When a belt tensioner fails, the drive belt may slip off the pulleys, causing a loss of power to engine components.

-

Point 2: Noisy Operation

A failing belt tensioner can result in noisy operation as the drive belt vibrates and rubs against engine components.

-

Point 3: Engine Overheating

Without proper tension, the drive belt may not adequately power the water pump, leading to engine overheating.

-

Point 4: Battery Drain

If the drive belt slips due to a failing tensioner, it can cause the alternator to work harder, draining the battery.

-

Point 5: Component Damage

A failing belt tensioner can cause premature wear on the drive belt and other engine components, leading to costly repairs.

How do I know if my belt tensioner pulley is bad?

-

Point 1: Squeaking or Grinding Noise

If you hear a squeaking or grinding noise coming from the engine area, it may indicate a bad belt tensioner pulley.

-

Point 2: Visible Wear or Damage

Inspect the belt tensioner pulley for any signs of wear, cracks, or damage that could affect its performance.

-

Point 3: Belt Misalignment

If the drive belt appears misaligned or off-center on the pulleys, it could be due to a faulty belt tensioner pulley.

-

Point 4: Tension Loss

If the drive belt feels loose or has decreased tension, the belt tensioner pulley may be failing to maintain proper tension.

-

Point 5: Engine Performance Issues

Poor engine performance, such as decreased power or stalling, could be a symptom of a failing belt tensioner pulley.

-

Point 6: Excessive Vibrations

If you notice excessive vibrations coming from the engine, it could be due to a worn-out belt tensioner pulley.

Advantages of Belt Tensioner Pulley

-

Point 1: Improved Engine Performance

The belt tensioner pulley ensures proper tension on the drive belt, leading to improved engine performance.

-

Point 2: Extended Component Lifespan

By maintaining correct belt tension, the belt tensioner pulley helps extend the lifespan of engine components.

-

Point 3: Reduced Maintenance Costs

Properly functioning belt tensioner pulleys can help reduce maintenance costs by preventing premature wear on engine parts.

-

Point 4: Smooth Operation

With a high-quality belt tensioner pulley, the engine operates smoothly and efficiently, minimizing noise and vibrations.

-

Point 5: Easy Installation

Replacing a belt tensioner pulley is a straightforward process, making it easy to maintain your vehicle's performance.

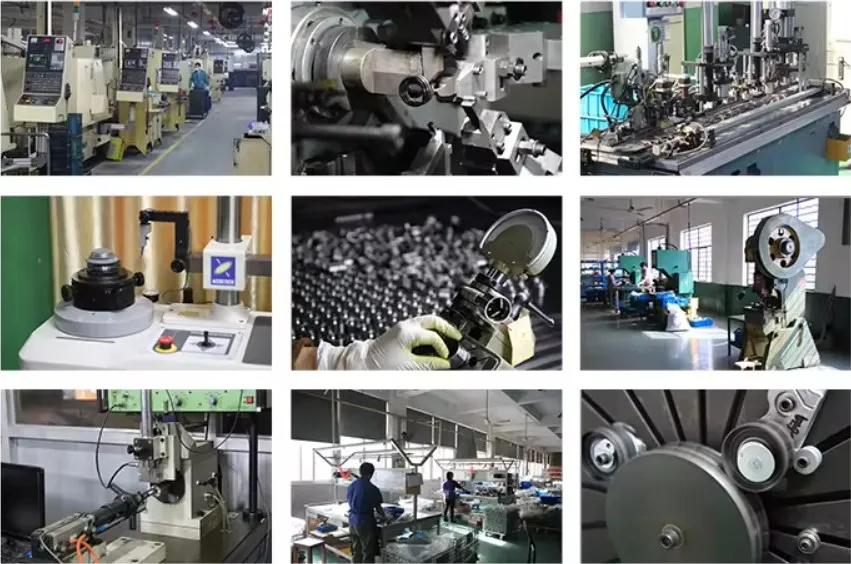

Process of Belt Tensioner Pulley

-

Mold

The belt tensioner pulley is first created using a mold to shape the components.

-

Casting

Once the mold is prepared, the molten raw materials are cast into the mold to form the pulley.

-

Raw Materials

High-quality raw materials are used to ensure the durability and performance of the belt tensioner pulley.

-

Production

The pulley undergoes production processes to refine its shape and structure for optimal function.

-

Testing

Each belt tensioner pulley is rigorously tested to ensure it meets quality and performance standards.

-

Antirust Treatment

Antirust treatments are applied to the pulley to protect it from corrosion and enhance longevity.

-

Seperate Inspection

The pulley undergoes a separate inspection to verify its quality and functionality before distribution.

-

Marking

Each belt tensioner pulley is marked with relevant information for identification and traceability.

Should I replace belt tensioner or just pulley?

-

Point 1: Inspection

Inspect both the belt tensioner and pulley for wear and damage before deciding on replacement.

-

Point 2: Age of Components

Consider the age of the belt tensioner and pulley, as older components may be more prone to failure.

-

Point 3: Cost-Effectiveness

Determine if replacing both components together would be more cost-effective in the long run.

-

Point 4: Performance Issues

If you experience performance issues with the belt tensioner or pulley, it may be time for replacement.

-

Point 5: Professional Advice

Consult a professional mechanic to assess the condition of the belt tensioner and pulley for accurate recommendations.

How does a belt tensioner pulley work?

-

Point 1: Tension Adjustment

The belt tensioner pulley adjusts the tension on the drive belt to ensure optimal power transfer.

-

Point 2: Component Connection

By connecting to various engine components, the belt tensioner pulley helps power essential functions.

-

Point 3: Rotation Mechanism

The pulley rotates smoothly to maintain consistent tension and prevent slippage of the drive belt.

-

Point 4: Load Distribution

The belt tensioner pulley evenly distributes the load on the drive belt, reducing wear on components.

-

Point 5: Engine Efficiency

By ensuring proper tension, the belt tensioner pulley contributes to the overall efficiency and performance of the engine.

About HZPT

HZPT was established in 2006 and is a leading manufacturer of precision and high-speed transmission components, headquartered in Hangzhou. We specialize in producing various machined parts and can create a wide range of complex products tailored to your needs.

Before establishing our overseas sales team, we started producing 3D printer accessories, anti-theft screws and nuts, camera mounts, and more. We also offer assembly production services to streamline the process and save time and costs. Whether your project is large or small, we strive to provide you with the highest quality, most competitive components, and superior service.

Get us involved early, and we will help you spend wisely!