Introduction to Belt Tensioner Pulley

Design and Working Principle of Belt Tensioner Pulley

The belt tensioner pulley is designed to maintain proper tension on the engine belt. It is a crucial component in the engine system that ensures smooth operation and prevents slippage. The working principle of the belt tensioner pulley is to apply the necessary force to keep the belt tight and prevent any slack that may cause issues with the engine's performance.

What happens when a belt tensioner fails?

1. Belt Slippage

When a belt tensioner fails, it can lead to belt slippage, which can cause various engine problems and reduce overall performance.

2. Noisy Operation

A failing belt tensioner can produce noise due to increased friction and improper belt alignment.

3. Engine Overheating

If the belt tensioner fails, it may cause the engine to overheat due to inadequate cooling system operation.

4. Loss of Power Steering

Failure of the belt tensioner can result in the loss of power steering, making it difficult to steer the vehicle.

5. Engine Stalling

In severe cases, a failed belt tensioner can cause the engine to stall, leading to potential safety hazards.

How do I know if my belt tensioner pulley is bad?

1. Squeaking or squealing noises coming from the engine

If you hear unusual noises while the engine is running, it could indicate a problem with the belt tensioner pulley.

2. Visible wear or damage on the pulley

Inspect the belt tensioner pulley for any signs of wear, cracks, or damage that may indicate a need for replacement.

3. Excessive belt vibration

If the belt tensioner pulley is bad, it may cause excessive belt vibration, affecting engine performance.

4. Misaligned or loose belt

A misaligned or loose belt could be a sign of a failing belt tensioner pulley.

5. Engine overheating

If your engine is overheating, it could be due to a malfunctioning belt tensioner pulley affecting the cooling system.

Advantages of Belt Tensioner Pulley

1. Improved engine performance

The belt tensioner pulley ensures proper belt tension, leading to improved engine performance.

2. Enhanced durability

High-quality materials and precise design contribute to the durability of the belt tensioner pulley.

3. Reduced maintenance costs

By preventing belt slippage and other issues, the belt tensioner pulley helps reduce maintenance costs.

4. Optimal engine cooling

A functioning belt tensioner pulley ensures optimal engine cooling, preventing overheating.

5. Smooth engine operation

With the right tension on the belt, the engine operates smoothly without any disruptions.

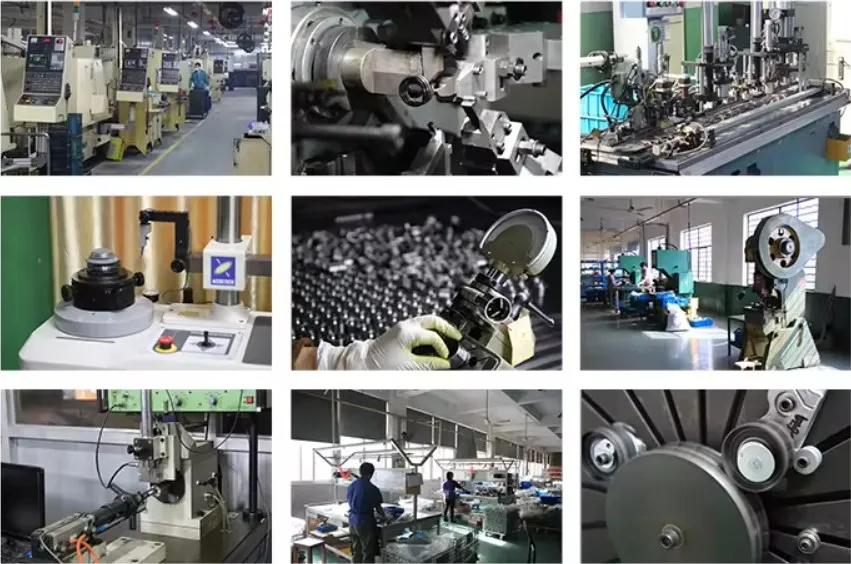

Process of Belt Tensioner Pulley

Mold

The mold is created based on the design specifications to form the belt tensioner pulley.

Casting

The raw materials are poured into the mold to create the initial shape of the pulley.

Raw materials

High-quality materials are used to ensure the durability and performance of the belt tensioner pulley.

Production

The pulley is manufactured with precision and attention to detail to meet quality standards.

Testing

Each belt tensioner pulley undergoes rigorous testing to ensure it meets performance requirements.

Antirust treatment

The pulley is treated to prevent rust and corrosion, extending its lifespan.

Separate inspection

Before assembly, each pulley is inspected individually to ensure quality control.

Marking

Each pulley is marked with specific information for identification and traceability.

Should I replace belt tensioner or just pulley?

1. Consider the extent of damage

If both the belt tensioner and pulley are damaged, it's recommended to replace both for optimal performance.

2. Age of the components

If the belt tensioner and pulley are old, replacing both can prevent future issues and ensure reliability.

3. Cost-effective solution

Replacing both components together can be a cost-effective solution in the long run compared to separate replacements.

4. Preventative maintenance

Replacing both the belt tensioner and pulley as part of regular maintenance can prevent unexpected failures.

5. Consultation with a professional

Seeking advice from a professional mechanic can help determine whether to replace both components or just the pulley.

How does a belt tensioner pulley work?

1. Tension adjustment

The belt tensioner pulley adjusts the tension of the engine belt to prevent slippage and ensure proper operation.

2. Maintenance of belt alignment

By keeping the belt aligned, the tensioner pulley helps prevent wear and tear on the belt and other engine components.

3. Reduction of engine noise

A properly functioning belt tensioner pulley can reduce noise by maintaining the correct tension on the belt.

4. Prevention of belt damage

With the right tension, the belt tensioner pulley prevents damage to the belt and extends its lifespan.

5. Overall engine performance

The belt tensioner pulley plays a crucial role in maintaining overall engine performance by ensuring proper belt tension.

About HZPT

Established in 2006, HZPT is a leading manufacturer of precision transmission components based in Hangzhou. We specialize in producing various engineered parts and can customize products to meet your specific needs. Our company has a strong reputation in Europe and America for providing high-quality products, competitive pricing, and excellent service. We offer a range of services from production to assembly, ensuring top-notch quality and cost-efficiency. Partner with HZPT for reliable, innovative solutions tailored to your requirements.