Product Description

Products Description:

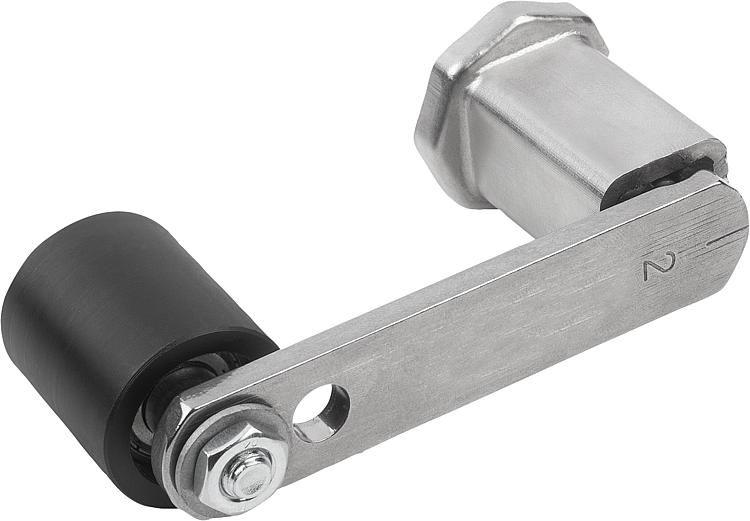

| Model | Elevator Speed Limiter Tensioner Tension Pulley 18KG | ||||

| Guarantee | 1 Year | ||||

| Delivery time | 5 Working days | ||||

| Package | Standard Box | ||||

Products Picture:

Company Information:

Workshop:

CE Certifications:

Advantages

1. Local Installation and after-sales service team

2. Remote wireless control

3. All main parts with CE certification

4. OEM for Ots Most parts same as Kone,Ots with Famous Brand

5. Multiple security protection to ensure safety

6. Less maintance cost, All our parts with Brand can easily buy from market

7. Very Smooth & Steady, make you feel like on the ground

8. Long-term guarantee

Work Shop

Partner & Projects

FAQ

1. The Elevator Stable and Safe?

We with more than 10years production experience. Currently working with Ots,Kone,and customers from more than 20countries.Our Products are Qualified with ISO9001,CE/EN81,EAC,KC.All the main parts which we use is international famous brand,make our elevator comes premium level.

2.How To Install and Maintain ?

We have been cooperated with elevator installation company more than 20countries,we never stop finding installation partner in other country everyday.To ensure our customer can enjoy both good quality and after-sales service.

3. Will The Elevator Drop Down or Clamp People Suddenly?

Our elevator get 6 lines protection ,In Machineroom,Elevator Door,Bottom of shaft. It will enter into the protection system automaticly if there is any issue .The elevator will not have such situation if the after service goes well.That's why we have so many parters all over the world.

4. Any Cerifications ?

We are qualified with CE/EN81,EAC/CU-TR,KC,TUV Certificates.You are full protected.

Choose us, ur wise choice!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1year |

|---|---|

| Warranty: | 1year |

| Type: | Control System |

| Suitable for: | Elevator |

| Load Capacity: | 5000kg |

| Persons: | >20 |

| Customization: |

Available

| Customized Request |

|---|

How does the size and design of a tension pulley impact its performance?

The size and design of a tension pulley have a significant impact on its performance in various applications. Here's a detailed explanation of how the size and design of a tension pulley influence its performance:

1. Size: The size of a tension pulley affects its mechanical advantage and the amount of contact area with the belt. A larger pulley diameter increases the effective radius around which the belt wraps, resulting in increased belt contact. This larger contact area enhances the grip between the belt and pulley, improving power transfer and reducing the likelihood of slippage. A larger tension pulley also allows for a more gradual bend radius, reducing stress concentrations on the belt and extending its lifespan.

2. Design: The design of a tension pulley encompasses various factors, including the shape, profile, and materials used. The design influences the pulley's ability to guide the belt, distribute tension, and minimize wear. Here are some specific design considerations and their impact on performance:

a. Pulley Profile: The profile of a tension pulley refers to its shape and contour. Common profiles include flat, crowned, and v-shaped. A crowned pulley has a slightly curved surface, which helps center the belt and maintain proper tracking. This design reduces the risk of belt misalignment and enhances the pulley's self-cleaning ability. V-shaped pulleys are often used with V-belts for increased grip and improved power transmission. The choice of pulley profile depends on the specific application and the type of belt being used.

b. Pulley Surface: The surface texture and finish of a tension pulley impact its frictional characteristics and interaction with the belt. A smooth and polished surface reduces friction, minimizing belt wear and heat generation. However, in certain applications where additional traction is required, such as in high-torque situations, pulleys with textured or coated surfaces may be used to increase grip and prevent slippage.

c. Pulley Material: The material used in the construction of a tension pulley affects its durability, wear resistance, and overall performance. Common materials include steel, cast iron, aluminum, and various engineering plastics. Steel and cast iron pulleys are known for their strength and durability, making them suitable for heavy-duty applications. Aluminum pulleys are lighter and corrosion-resistant, making them ideal for certain environments. Engineering plastics, such as nylon or polyurethane, offer advantages like reduced noise, improved friction, and resistance to chemicals or abrasion.

d. Pulley Bearings: The design and quality of the bearings used in the tension pulley impact its smoothness of rotation and overall performance. High-quality bearings with low friction enable efficient power transmission and reduce wear on the pulley and belt. Properly lubricated and sealed bearings also contribute to the longevity and reliability of the tension pulley.

e. Pulley Configuration: The configuration of tension pulleys in a system, such as the number of pulleys and their arrangement, can impact performance. Multiple tension pulleys can distribute the load more evenly across the belt, reducing localized stress and improving overall system efficiency. The proper positioning and alignment of tension pulleys also play a crucial role in maintaining belt tension, tracking, and minimizing wear.

In summary, the size and design of a tension pulley significantly affect its performance. The size determines the contact area with the belt and the mechanical advantage, influencing grip, power transfer, and belt lifespan. The design considerations, including pulley profile, surface texture, material selection, bearing quality, and configuration, impact belt tracking, tension distribution, wear resistance, and overall system efficiency. Choosing the appropriate size and design based on the specific application requirements is essential for maximizing the performance and longevity of tension pulleys.

How are tension pulleys used in the production of electronics and semiconductors?

Tension pulleys play a crucial role in the production of electronics and semiconductors, particularly in manufacturing processes that involve precision and delicate handling of materials. They are utilized in various stages of production to ensure accurate positioning, controlled movement, and proper tensioning of components and materials. Here's a detailed explanation of how tension pulleys are used in the production of electronics and semiconductors:

1. Material Handling: Tension pulleys are often used in the material handling processes during the production of electronics and semiconductors. They are employed in conveyor systems to guide and tension delicate materials such as thin films, wafers, and flexible circuit boards. Tension pulleys help ensure smooth and controlled movement of these materials, minimizing the risk of damage or misalignment during transportation between different production stages.

2. Web Processing: In the production of electronic components such as printed circuit boards (PCBs) or flexible displays, tension pulleys are utilized in web processing systems. These systems handle continuous rolls of materials, such as films, foils, or substrates, and involve processes like coating, laminating, or die-cutting. Tension pulleys are critical in maintaining the proper tension of the web as it moves through various processing stations, ensuring precise alignment and consistent quality of the produced components.

3. Wire and Cable Manufacturing: Tension pulleys are extensively used in the manufacturing of wires and cables for electronic applications. They are employed in wire drawing machines and cable extrusion lines to maintain consistent tension on the wire or cable being produced. Tension pulleys help control the speed and tension of the wire or cable, ensuring uniform diameter, proper insulation, and reliable electrical properties throughout the manufacturing process.

4. Component Assembly: Tension pulleys are integrated into assembly systems for the precise positioning and alignment of electronic components. For example, in surface mount technology (SMT) processes, tension pulleys are utilized in pick-and-place machines to guide and tension the reels of surface mount devices (SMDs) as they are accurately placed onto PCBs. Tension pulleys play a crucial role in ensuring the controlled movement and accurate placement of components, contributing to the overall quality and reliability of electronic assemblies.

5. Wafer Processing: In semiconductor manufacturing, tension pulleys are employed in wafer processing equipment. They are used in systems such as chemical mechanical planarization (CMP) or wafer dicing machines. Tension pulleys help control the tension and movement of the wafers during processes like polishing, grinding, or dicing, ensuring precise material removal, accurate alignment, and minimizing the risk of wafer breakage or damage.

It is important to note that tension pulleys used in the production of electronics and semiconductors are often designed with precision and controlled motion in mind. They are typically made from materials that minimize particle generation or contamination and incorporate features such as low friction bearings or special coatings to ensure smooth operation without compromising the cleanliness of the production environment.

In summary, tension pulleys are extensively utilized in the production of electronics and semiconductors. They contribute to accurate material handling, controlled movement, and precise positioning of components and materials, ultimately enhancing the quality, reliability, and efficiency of the manufacturing processes in the electronics and semiconductor industry.

In which industries and applications are tension pulleys commonly employed?

Tension pulleys, also known as idler pulleys or belt tensioners, find widespread use in various industries and applications where maintaining proper tension in belts or chains is essential. Their versatility and effectiveness make them a critical component in numerous mechanical systems. Here's a detailed explanation of the industries and applications where tension pulleys are commonly employed:

1. Automotive Industry: Tension pulleys are extensively used in automobiles for maintaining tension in the engine's accessory belts, such as the serpentine belt. They ensure proper power transfer to components like the alternator, air conditioning compressor, power steering pump, and water pump. Tension pulleys are also employed in timing belt systems to synchronize the rotation of the engine's camshaft and crankshaft.

2. Material Handling and Conveyor Systems: In industries like manufacturing, logistics, and mining, tension pulleys are widely utilized in conveyor systems. They help maintain tension in the conveyor belts, ensuring efficient movement of materials. Tension pulleys are crucial for preventing belt slippage and maintaining proper engagement with the pulleys, enabling reliable and continuous material handling operations.

3. Agricultural Machinery: Tension pulleys are employed in various agricultural machinery, including combines, harvesters, and balers. They play a vital role in maintaining tension in belts or chains that power different components, such as the cutting mechanisms, conveyor systems, or the drive systems for grain or hay handling.

4. Industrial Machinery: Tension pulleys are commonly used in a wide range of industrial machinery and equipment. They are found in textile manufacturing machines, printing presses, packaging equipment, woodworking machinery, and more. Tension pulleys help maintain proper tension in belts or chains that drive various components, ensuring accurate and reliable operation of the machinery.

5. Power Transmission Systems: Tension pulleys are vital in power transmission systems, such as those used in pumps, compressors, and generators. They help maintain tension in belts or chains that transmit power from the motor to the driven components. Tension pulleys ensure efficient power transfer, prevent belt slippage, and minimize vibrations and noise in the system.

6. Fitness Equipment: Tension pulleys are commonly employed in fitness equipment, including treadmills, stationary bikes, and weightlifting machines. They help maintain tension in the belts or cables used for resistance and ensure smooth operation and consistent resistance levels during workouts.

7. Construction and Heavy Equipment: Tension pulleys are utilized in construction machinery and heavy equipment, such as excavators, cranes, and loaders. They are employed in the drive systems for components like conveyor belts, winches, and hydraulic systems, ensuring proper tension and reliable operation even under demanding conditions.

8. Marine and Marine Equipment: Tension pulleys find applications in marine systems and equipment, including boat engines, winches, and marine propulsion systems. They help maintain tension in belts or chains that drive components like water pumps, alternators, and steering mechanisms, ensuring reliable performance in marine environments.

9. Textile Industry: Tension pulleys are crucial in textile machines, such as spinning machines, weaving looms, and knitting machines. They help maintain tension in belts or chains that drive the various components of these machines, ensuring precise movement and control of the textile materials.

10. Printing and Paper Industry: Tension pulleys are employed in printing presses, paper manufacturing machines, and paper converting equipment. They help maintain tension in belts or chains used for paper feeding, printing, cutting, and other processes, ensuring accurate registration and reliable operation.

In summary, tension pulleys are commonly employed in a wide range of industries and applications, including automotive, material handling, agriculture, industrial machinery, power transmission systems, fitness equipment, construction, marine, textile, printing, and paper industries. Their ability to maintain proper tension in belts or chains contributes to the reliable and efficient operation of various mechanical systems across these sectors.

editor by CX

2024-03-02