Product Description

Basic Info

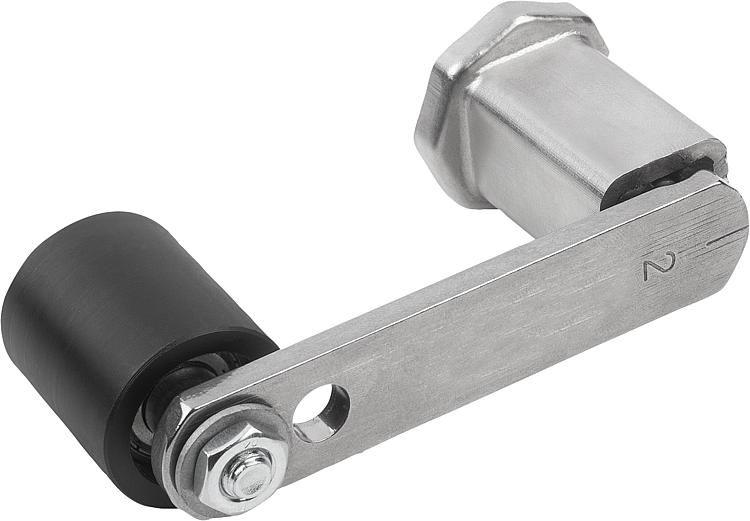

| Model NO. | VG260006571 |

| Type | Transmission System |

| Color | Silver and Black |

| Main Market | Main Market |

| Material | Steel and Plastic |

| Warranty | 3 Months |

| Aplication | HOWO, CHINAMFG Prince |

| Transport Package | Customized Design Is Available |

| Specification | 1PC/BOX |

| Origin | China |

| HS Code | 87089992 |

We can supply :

CHINAMFG Engine and spare parts

CHINAMFG Engine and spare parts

CHINAMFG Engine and spare parts

Hino Engine and spare parts

CHINAMFG Engine and spare parts

CHINAMFG Engine and spare parts

Dachai Engine and spare parts

CHINAMFG (HangZhou) Engine and spare parts

CHINAMFG Engine and spare parts

Company profile:

Our company has focused on truck parts and engineering machinery parts export for over 5 years. It covers truck of Sinotruck, Shacman, Foton, FAW, SANY, JAC, Hino, Isuzu, CHINAMFG etc., engine of CHINAMFG & WEICHAI, Yuchai, Shangchai, Xichai, etc, and engineering machinery of Liugong, SDLG, CHINAMFG etc.

Our most of parts have 3 kinds of grades:

1. Original

2. OEM

3. Copy

All products are certified to international quality standards ISO9001 and TS16949. It can satisfy the distributor to get profit and the transporter to get high quality.

Our warehouse covers area more than 2000 square CHINAMFG with 26 employees, and the office is more than 300 square meters. We warmly welcome you to visit our company.

Our sevice:

1.Customized design, logo, color

2. Long term after-sale service

3. Multi payment terms

4. Multi delivery terms

FAQ

Q: What is your main products?

A:We mainly sell truck parts and diesel engine parts.

Q: Do you have any other products?

A:Yes, we have many other diesel engine spare parts.

Q: How to place orders?

A :The order is from your inqiuries.

1,Confrim PI (the engine model, price, quantity, packing, delivery time, shipping way, time of payment).

2,You make payment and send us receipt of payment.

3,We get to start preparing the goods when we receive payment from you. (The goods will be sent between 48 hours to 72 hours if we have in stock. The goods will be sent before the delivery time and the sample will send to you for checking.)

4,We would deliver goods after we get balance from you. The order finish when you get goods and feel satisfied.

Q: What is the MOQ?

A:We provide sample and will arrange goods as your requirements.

Q: How to make payment?

A:After you confirm PI, you can pay thruogh Alibaba Trade Assurance,Wire transfer, Western union, Paypal, Cash. (The production order can be pay 30% deposit first, after we arranged well, then you pay the balance.)

Q: Could you give guarantee ?

A:Yes, 1 year warranty.

Q: What kind of packing you can provide?

A:We can provide packing as your requirements or neutral packing or our own trademark packing.

If you are interested in our parts, please feel to cotact:

Ms. Lea Feng

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Engine |

|---|---|

| Certification: | ISO9001 |

| Brake System Parts: | Transmission |

| Transmission System Parts: | Transmission Shaft |

| Steering System Parts: | Steering Transmission Device |

| Color: | Silvery White |

What safety considerations should be kept in mind when using tension pulleys?

When using tension pulleys, it is crucial to prioritize safety to prevent accidents and ensure the well-being of personnel. Here are some important safety considerations to keep in mind:

1. Proper Guarding: Tension pulleys should be adequately guarded to prevent accidental contact with moving parts. Guards should be designed and installed in accordance with applicable safety standards and regulations. They should be securely attached and provide sufficient coverage to prevent access to the pulley and associated belts, reducing the risk of entanglement or injury.

2. Lockout/Tagout Procedures: Before performing any maintenance or repair tasks on machinery or equipment with tension pulleys, proper lockout/tagout procedures should be followed. This involves isolating the power source, de-energizing the system, and securing it with locks or tags to prevent accidental startup. Lockout/tagout procedures help protect personnel from unexpected movement or energization of the pulleys during maintenance activities.

3. Training and Awareness: Adequate training should be provided to personnel involved in the operation, maintenance, and servicing of machinery with tension pulleys. They should be educated about the potential hazards associated with tension pulleys, such as entanglement, pinch points, and rotating parts. Training should cover safe work practices, proper use of personal protective equipment (PPE), and emergency procedures. Regular safety reminders and refresher training sessions are also beneficial to maintain awareness and reinforce safe behaviors.

4. Proper Use of Personal Protective Equipment (PPE): Depending on the specific hazards present, appropriate personal protective equipment should be worn by personnel working with tension pulleys. This may include safety glasses, gloves, hearing protection, and, if necessary, respiratory protection. PPE helps protect against potential injuries from flying debris, contact with moving parts, and exposure to noise or airborne contaminants.

5. Maintaining Proper Belt Tension: It is important to maintain proper belt tension within the recommended range specified by the manufacturer. Insufficient tension can result in belt slippage, while excessive tension can overload the system and lead to premature wear or failure. Regular inspections and adjustments should be performed to ensure the tension is within the specified limits. This helps maintain safe and efficient operation of the tension pulleys and associated equipment.

6. Regular Inspection and Maintenance: Tension pulleys should be regularly inspected for signs of wear, damage, or misalignment. Any issues should be promptly addressed to prevent potential hazards. Routine maintenance, such as cleaning, lubrication, and replacement of worn components, should be carried out as per the manufacturer's recommendations. Regular inspections and maintenance help identify and rectify potential safety concerns before they escalate.

7. Proper Lifting and Handling: When handling tension pulleys or performing maintenance tasks, proper lifting techniques and equipment should be used to prevent strains or injuries. Pulleys can be heavy and awkward to handle, so mechanical lifting aids or assistance from trained personnel may be necessary. Adequate precautions should be taken to prevent pulleys from falling or rolling during transportation or installation.

8. Clear Communication and Signage: Clear communication and proper signage should be in place to indicate the presence of tension pulleys and associated hazards. Warning signs, labels, or color-coded markings can help alert personnel to potential dangers and remind them of safety precautions. Safety instructions, including emergency contact information, should be prominently displayed in the vicinity of tension pulleys.

9. Regular Risk Assessments: Conducting regular risk assessments specific to the machinery and equipment using tension pulleys is essential. This helps identify potential hazards, assess their severity and likelihood, and implement appropriate control measures. Risk assessments should be reviewed periodically and updated as necessary to account for changes in equipment, processes, or operating conditions.

By adhering to these safety considerations, the risks associated with tension pulleys can be minimized, creating a safer working environment for personnel and reducing the likelihood of accidents or injuries.

How do tension pulleys contribute to the functioning of garage door systems?

Tension pulleys play a vital role in the functioning of garage door systems. They are integral components that help support and guide the movement of the garage door, ensuring smooth operation, proper tensioning of the lifting cables, and efficient transfer of force. Here's a detailed explanation of how tension pulleys contribute to the functioning of garage door systems:

1. Lifting Mechanism: Garage doors typically operate using a lifting mechanism that involves torsion springs or extension springs, along with lifting cables. Tension pulleys are used to guide and route the lifting cables, which are attached to the bottom of the garage door and connected to the spring system. As the springs are tensioned or extended, the tension pulleys ensure that the lifting cables move smoothly along the pulley tracks, facilitating the upward or downward movement of the garage door.

2. Tensioning of Lifting Cables: Tension pulleys in garage door systems help maintain the proper tension in the lifting cables. The cables need to be appropriately tensioned to support the weight of the garage door and ensure balanced and controlled movement. Tension pulleys provide a point of contact for the lifting cables, allowing them to wrap around the pulleys and adjust their tension as the door opens or closes. This proper tensioning prevents cable slack, maintains stability, and ensures safe and reliable operation of the garage door.

3. Smooth and Balanced Operation: Tension pulleys contribute to the smooth and balanced operation of garage door systems. As the lifting cables move along the tension pulleys, they help distribute the force evenly, preventing excessive strain on specific components. This balanced force distribution minimizes the risk of cable or pulley damage and ensures that the garage door moves up and down smoothly without any jerking or binding. The smooth operation facilitated by tension pulleys enhances user convenience and prolongs the lifespan of the garage door system.

4. Noise Reduction: Tension pulleys also play a role in reducing noise during the operation of garage door systems. By guiding the lifting cables and providing smooth movement, they help minimize friction and vibrations that can contribute to noise generation. The proper tensioning and alignment of the cables achieved through tension pulleys contribute to quieter operation, reducing disturbances for occupants and neighbors when the garage door is opened or closed.

5. Component Protection: Tension pulleys help protect various components of the garage door system. By maintaining proper tension in the lifting cables, they prevent excessive stress or strain on other components such as the springs, tracks, and door panels. This protection extends the lifespan of these components, reducing the likelihood of premature wear, damage, or costly repairs. Tension pulleys also contribute to the overall safety and reliability of the garage door system, minimizing the risk of accidents or malfunctions.

It is important to note that tension pulleys in garage door systems should be regularly inspected and maintained to ensure their proper functioning. Lubrication and periodic adjustments may be necessary to optimize their performance and extend their lifespan.

In summary, tension pulleys are essential components in garage door systems. They facilitate the movement of lifting cables, maintain proper tension, support balanced operation, reduce noise, and protect various components. By incorporating tension pulleys, garage door systems operate smoothly, safely, and reliably, providing convenience and security for homeowners.

In which industries and applications are tension pulleys commonly employed?

Tension pulleys, also known as idler pulleys or belt tensioners, find widespread use in various industries and applications where maintaining proper tension in belts or chains is essential. Their versatility and effectiveness make them a critical component in numerous mechanical systems. Here's a detailed explanation of the industries and applications where tension pulleys are commonly employed:

1. Automotive Industry: Tension pulleys are extensively used in automobiles for maintaining tension in the engine's accessory belts, such as the serpentine belt. They ensure proper power transfer to components like the alternator, air conditioning compressor, power steering pump, and water pump. Tension pulleys are also employed in timing belt systems to synchronize the rotation of the engine's camshaft and crankshaft.

2. Material Handling and Conveyor Systems: In industries like manufacturing, logistics, and mining, tension pulleys are widely utilized in conveyor systems. They help maintain tension in the conveyor belts, ensuring efficient movement of materials. Tension pulleys are crucial for preventing belt slippage and maintaining proper engagement with the pulleys, enabling reliable and continuous material handling operations.

3. Agricultural Machinery: Tension pulleys are employed in various agricultural machinery, including combines, harvesters, and balers. They play a vital role in maintaining tension in belts or chains that power different components, such as the cutting mechanisms, conveyor systems, or the drive systems for grain or hay handling.

4. Industrial Machinery: Tension pulleys are commonly used in a wide range of industrial machinery and equipment. They are found in textile manufacturing machines, printing presses, packaging equipment, woodworking machinery, and more. Tension pulleys help maintain proper tension in belts or chains that drive various components, ensuring accurate and reliable operation of the machinery.

5. Power Transmission Systems: Tension pulleys are vital in power transmission systems, such as those used in pumps, compressors, and generators. They help maintain tension in belts or chains that transmit power from the motor to the driven components. Tension pulleys ensure efficient power transfer, prevent belt slippage, and minimize vibrations and noise in the system.

6. Fitness Equipment: Tension pulleys are commonly employed in fitness equipment, including treadmills, stationary bikes, and weightlifting machines. They help maintain tension in the belts or cables used for resistance and ensure smooth operation and consistent resistance levels during workouts.

7. Construction and Heavy Equipment: Tension pulleys are utilized in construction machinery and heavy equipment, such as excavators, cranes, and loaders. They are employed in the drive systems for components like conveyor belts, winches, and hydraulic systems, ensuring proper tension and reliable operation even under demanding conditions.

8. Marine and Marine Equipment: Tension pulleys find applications in marine systems and equipment, including boat engines, winches, and marine propulsion systems. They help maintain tension in belts or chains that drive components like water pumps, alternators, and steering mechanisms, ensuring reliable performance in marine environments.

9. Textile Industry: Tension pulleys are crucial in textile machines, such as spinning machines, weaving looms, and knitting machines. They help maintain tension in belts or chains that drive the various components of these machines, ensuring precise movement and control of the textile materials.

10. Printing and Paper Industry: Tension pulleys are employed in printing presses, paper manufacturing machines, and paper converting equipment. They help maintain tension in belts or chains used for paper feeding, printing, cutting, and other processes, ensuring accurate registration and reliable operation.

In summary, tension pulleys are commonly employed in a wide range of industries and applications, including automotive, material handling, agriculture, industrial machinery, power transmission systems, fitness equipment, construction, marine, textile, printing, and paper industries. Their ability to maintain proper tension in belts or chains contributes to the reliable and efficient operation of various mechanical systems across these sectors.

editor by CX

2024-04-23