Design and Working Principle of Belt Tensioner Pulley

- The belt tensioner pulley is designed to maintain proper tension in the serpentine belt, ensuring smooth operation of engine components.

- It features a spring-loaded mechanism that automatically adjusts tension as the belt stretches over time, keeping it at the optimal level.

- The pulley itself is typically made of durable materials such as steel or aluminum to withstand the constant movement and tension.

- Its smooth surface reduces friction and wear on the belt, extending the lifespan of both the belt and other engine components.

- Overall, the belt tensioner pulley plays a crucial role in the efficient and reliable operation of the vehicle's engine system.

What happens when a belt tensioner fails?

- Loss of tension in the serpentine belt, leading to slippage and reduced performance of engine components.

- Unusual noises such as squealing or grinding coming from the engine area.

- Visible damage or wear on the belt tensioner pulley itself.

- Overheating of the engine due to improper functioning of cooling system components.

- Potential damage to other engine parts if the issue is not addressed promptly.

How do I know if my belt tensioner pulley is bad?

- Unusual squealing or grinding noises coming from the engine area.

- Visible wear or damage on the belt tensioner pulley.

- Difficulty in starting the engine or loss of power while driving.

- Visible signs of belt slippage or misalignment.

- Engine overheating or warning lights on the dashboard indicating an issue.

Advantages of Belt Tensioner Pulley

- Ensures proper tension in the serpentine belt for optimal engine performance.

- Reduces wear and tear on the belt and other engine components.

- Improves overall engine efficiency and longevity.

- Easy to install and compatible with a wide range of vehicle models.

- Cost-effective solution to prevent costly engine repairs in the future.

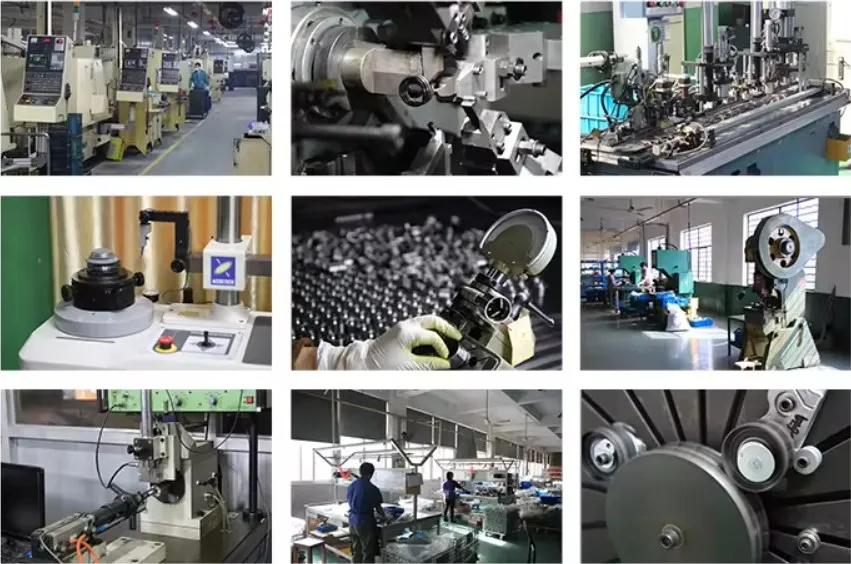

Process of Belt Tensioner Pulley

Mold:

The mold for the belt tensioner pulley is carefully designed to ensure accurate and consistent production.

Casting:

High-quality materials are melted and poured into the mold to form the shape of the pulley.

Raw Materials:

Durable materials such as steel or aluminum are used to ensure the longevity and performance of the pulley.

Production:

The pulley is manufactured using precision machinery to meet exact specifications.

Testing:

Each pulley undergoes rigorous testing to ensure quality and performance standards are met.

Antirust Treatment:

A special coating is applied to the pulley to protect it from corrosion and extend its lifespan.

Seperate Inspection:

Each pulley is individually inspected to guarantee it meets all quality requirements before packaging.

Marking:

Finally, the pulley is marked with necessary information for identification and traceability.

Should I replace belt tensioner or just pulley?

- If the belt tensioner is failing, it is recommended to replace the entire assembly for optimal performance.

- Replacing just the pulley may not address underlying issues with the tensioner mechanism.

- Consulting a professional mechanic for assessment and recommendation is advised.

- Replacing both the tensioner and pulley ensures long-term reliability and performance.

- Cost considerations and warranty coverage should also be taken into account.

How does a belt tensioner pulley work?

- The belt tensioner pulley is attached to a spring-loaded arm that exerts pressure on the serpentine belt.

- As the engine runs, the pulley maintains the correct tension in the belt to prevent slippage.

- Any stretching or wear in the belt is automatically compensated for by the tensioner pulley.

- This ensures smooth operation of engine components and prevents damage due to improper tension.

- The design of the pulley allows for easy installation and adjustment as needed.

About HZPT

HZPT, established in 2006, is a leading manufacturer of precision transmission components dedicated to pursuing accuracy and speed. Headquartered in Hangzhou, we specialize in producing various intricate parts and can customize products to meet your specific requirements. Before establishing an overseas sales team, we started producing 3D printer accessories, anti-theft screws and nuts, camera brackets, and more. We also provide one-stop assembly production services, eliminating middlemen to save time and costs. Regardless of your project size, we strive to offer the highest quality, most competitive parts, and the best service. Get us involved early, and we will help you spend wisely!