Design and Working Principle of Belt Tensioner Pulley

- The belt tensioner pulley is designed to maintain proper tension on the belt in the engine system.

- It is typically a small pulley connected to an adjustable arm that applies pressure to the belt.

- When the engine is running, the belt tensioner pulley rotates and ensures the belt stays in place.

- The working principle involves the pulley applying tension to the belt to prevent slipping and ensure efficient operation of engine components.

- This component plays a crucial role in the overall performance and longevity of the engine system.

What happens when a belt tensioner fails?

- Loss of tension in the belt, causing slippage and decreased performance.

- Excessive wear on the belt and other engine components.

- Noise from the engine due to the belt not being properly tensioned.

- Risk of belt coming off completely, leading to engine failure.

- Increased strain on the engine, reducing fuel efficiency.

How do I know if my belt tensioner pulley is bad?

- Strange noises coming from the engine, such as squealing or grinding.

- Visible wear or damage on the belt tensioner pulley.

- Difficulty starting the engine or frequent stalling.

- Visible misalignment of the belt or pulleys.

- Frequent belt replacement due to wear.

- Excessive vibration while the engine is running.

Advantages of Belt Tensioner Pulley

- Ensures proper tension on the belt for optimal engine performance.

- Reduces wear and tear on engine components.

- Improves overall engine efficiency and fuel economy.

- Easy to install and maintain.

- Helps prevent costly repairs by ensuring proper belt alignment.

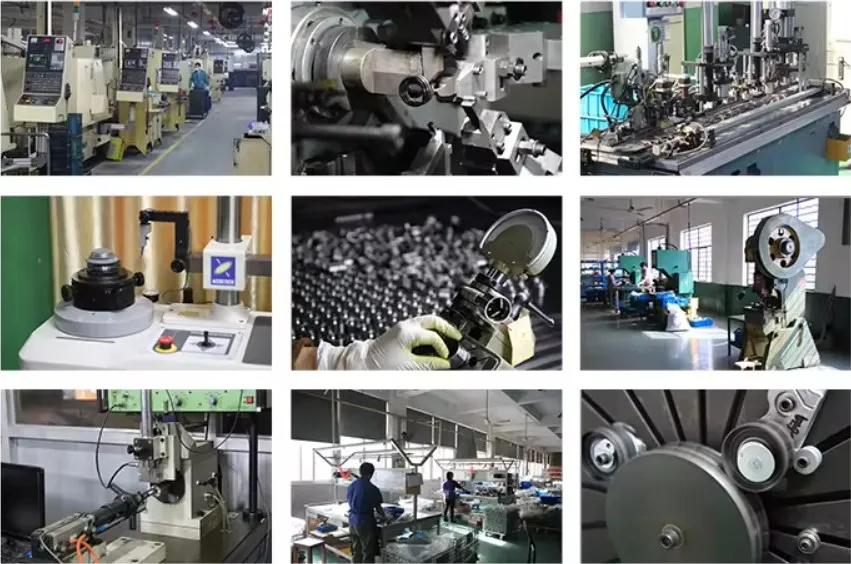

Process of Belt Tensioner Pulley

Mold

The mold is created to form the shape of the tensioner pulley.

Casting

The molten raw material is poured into the mold to create the pulley.

Raw Materials

High-quality materials are used to ensure durability and performance.

Production

The pulleys are manufactured according to specific design requirements.

Testing

Each pulley is tested for quality and performance before being shipped.

Antirust Treatment

A special coating is applied to prevent rust and corrosion.

Separate Inspection

Each pulley undergoes a final inspection to ensure it meets quality standards.

Marking

Product information and specifications are marked on the pulley for identification.

Should I replace belt tensioner or just pulley?

- It is recommended to replace the entire belt tensioner assembly if one component fails.

- This ensures optimal performance and prevents further issues down the line.

- Replacing only the pulley may not address underlying issues with the tensioner.

- Consult a mechanic for the best course of action based on the specific situation.

- Regular maintenance and inspection can help prevent premature failure.

How does a belt tensioner pulley work?

- The belt tensioner pulley is connected to an adjustable arm that applies pressure to the belt.

- As the engine runs, the pulley rotates and maintains tension on the belt.

- This prevents slippage and ensures efficient operation of engine components.

- The pulley works in conjunction with other pulleys to drive various engine systems.

- Proper tension on the belt is crucial for overall engine performance and longevity.

About HZPT

Founded in 2006, HZPT is a leading manufacturer of precision transmission components based in Hangzhou.

We specialize in producing various engineered parts and offer customization services to meet specific requirements.

Our products are widely acclaimed in Europe and America for their quality and competitive prices.

We provide top-notch services, the highest product quality, and competitive prices to our esteemed customers.