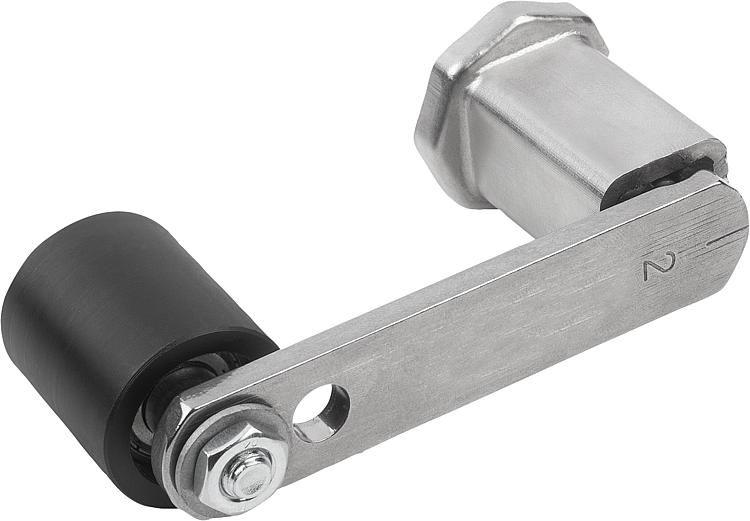

Design and Working Principle of Belt Tensioner Pulley

- The belt tensioner pulley is designed to maintain proper tension on the belt in a vehicle's engine.

- It is typically made of high-quality materials such as steel or aluminum to ensure durability.

- The pulley works by applying tension to the belt, preventing slippage and ensuring smooth operation of the engine.

- Its design includes bearings that allow it to rotate freely, reducing friction and wear on the belt.

- Overall, the belt tensioner pulley plays a crucial role in the proper functioning of the vehicle's engine system.

What happens when a belt tensioner fails?

- When a belt tensioner fails, it can lead to the belt slipping off or becoming loose, causing the engine to overheat.

- Failure of the tensioner can result in loud squealing noises coming from the engine due to the belt slipping.

- It can also cause accessories like the alternator or power steering pump to stop functioning properly.

- Ultimately, a failed belt tensioner can lead to complete engine failure if not addressed promptly.

- Regular inspection and maintenance of the belt tensioner pulley are essential to prevent such issues.

How do I know if my belt tensioner pulley is bad?

- Squeaking or squealing noises coming from the engine.

- Visible wear or damage on the pulley surface.

- Irregular belt wear patterns.

- Excessive belt slack or tension.

- Vibrations or shaking while the engine is running.

- Burning smell coming from the engine area.

Advantages of Belt Tensioner Pulley

- Ensures proper functioning of the engine system.

- Reduces maintenance costs by preventing belt slippage.

- Improves overall engine performance and efficiency.

- Increases the lifespan of the engine belt.

- Provides peace of mind for vehicle owners by ensuring reliable operation.

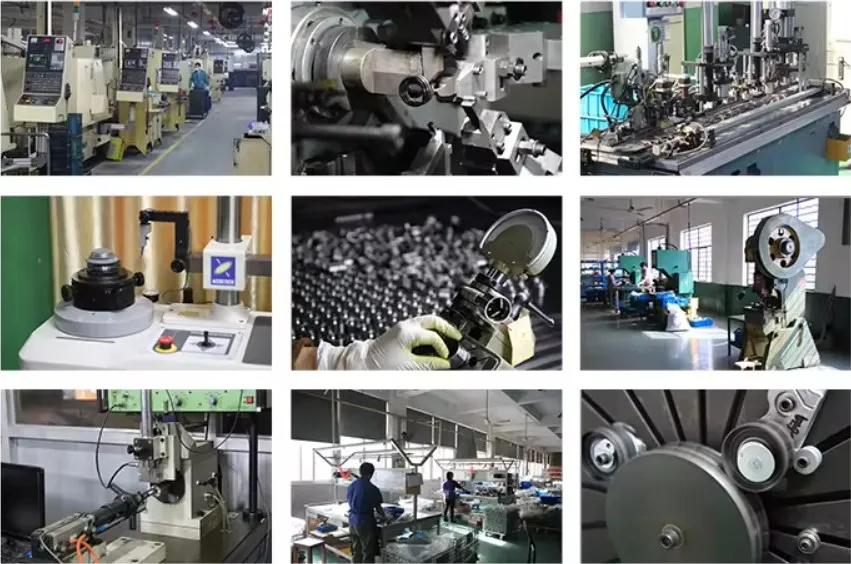

Process of Belt Tensioner Pulley

Mold

The mold for the belt tensioner pulley is carefully crafted to ensure precise dimensions and high-quality production.

Casting

The pulley is cast using advanced techniques to create a durable and reliable component for the engine system.

Raw Materials

High-quality materials such as steel or aluminum are used to manufacture the belt tensioner pulley.

Production

The production process involves precision machining and assembly to ensure the pulley meets industry standards.

Testing

Each pulley undergoes rigorous testing to verify its performance and durability before being shipped.

Antirust Treatment

A special antirust treatment is applied to the pulley to protect it from corrosion and ensure longevity.

Seperate Inspection

Individual inspection is carried out to check for any defects or imperfections in the pulley.

Marking

Each pulley is marked with essential information for easy identification and installation in the vehicle.

Should I replace belt tensioner or just pulley?

- If the tensioner is worn out or damaged, it is recommended to replace the entire assembly for optimal performance.

- Replacing just the pulley may be sufficient if the tensioner itself is still in good condition.

- Consulting with a professional mechanic is advisable to determine the best course of action.

- Regular maintenance and inspection can help prevent premature failure of the tensioner or pulley.

- Choosing high-quality replacement parts is essential for long-term reliability.

How does a belt tensioner pulley work?

- The belt tensioner pulley applies tension to the belt, ensuring it stays in place and operates smoothly.

- It rotates freely on bearings, reducing friction and wear on the belt.

- The pulley's design allows it to adjust tension automatically as the belt stretches over time.

- Proper tension from the pulley prevents slippage and ensures all engine components function correctly.

- In essence, the belt tensioner pulley plays a vital role in maintaining the integrity of the engine system.

About HZPT

Established in 2006, HZPT is a leading manufacturer of precision transmission components based in Hangzhou. We specialize in producing various machined parts and can customize products to meet your specific requirements. Our company is known for its dedication to quality, speed, and customer satisfaction. With a focus on innovation and efficiency, we provide top-notch products and services to customers in Europe and America. Choose HZPT for the best quality, competitive prices, and exceptional service.